You live in a world surrounded by metal. Most everything you touch, from your phone to your refrigerator and automobile, is made of metal. However, the word metal can refer to many different materials designed for specific purposes. For instance, the metal used for electrical wiring is not the same as what is used for hub caps.

So, what are the most common types of metal for metal fabrication?

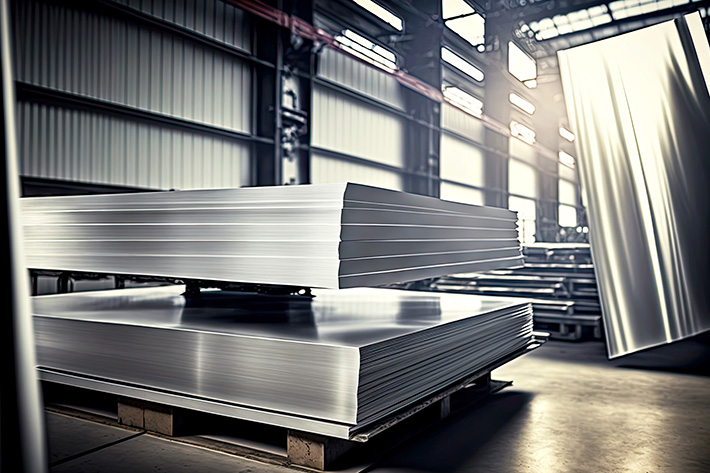

The three most common types of metal for fabrication are steel, aluminum, and copper. They have all been in use for a long time for a variety of industries, and new applications for metal are being invented every year.

Each kind of metal has a variety of types or grades. Carbon steel and stainless steel are both steels, but they have different properties that make them useful for different applications. Alloys are combinations of metals that are put together to achieve a certain property, such as being stronger or more heat resistant.

So, What are the Metals Best Used for?

Steel is used in a wide variety of industries, including construction, automotive, medical, and appliance manufacturing. Your office building has steel beams in it, your car engine is mostly steel, and your air conditioner has steel parts to make it run correctly. Its versatility makes it widely applicable when manufacturing anything from a skyscraper to a dishwasher. This metal is strong, durable, malleable, and a good conductor of heat and electricity.

Aluminum is in your life more than you realize. Other than the roll of foil in your kitchen, aluminum may also be part of your laptop because it is lightweight and doesn’t hold in heat. These properties, as well as being strong and resistant to corrosion, make them useful in the airline and spacecraft industries. Aluminum is also common in packaging, like for your favorite canned beverage.

Copper is used in the electronic industry, as well as the shipbuilding and construction fields. It has anticorrosive and antimicrobial properties, which makes it useful for the medical industry. Copper is used for pipes and wiring anywhere in homes, commercial buildings, ships, trains, and other types of transportation.

So, What are the Main Differences?

The functions of these metals overlap in some ways, but some distinctions separate them. Copper is more expensive than steel, but copper is a better conductor. Steel is stronger than copper but copper is more malleable.

Steel is heavier than aluminum, but aluminum can be less corrosive. Steel can also be cheaper. The lightweight characteristic of aluminum is what sets it apart from steel and makes it useful where a light metal is needed.

Copper is a better conductor than aluminum, but aluminum is cheaper. Copper is also more anticorrosive, but aluminum is lighter. Copper is more durable.

Related Questions

So, Why is it Important to Know the Differences?

If you understand the properties and benefits of each type of common metal, then you can make a better decision when buying appliances, repairing your home or vehicle, or any type of renovation. It is good to understand what material best fits your situation.

So, What Metals Are Combined to Make Steel?

Essentially, steel is an alloy of iron and carbon. Steel gets its strength from the amount of carbon added to iron, which is not as strong on its own. Other metals can be added to the mix of iron and carbon to make it stronger, more malleable, or other such characteristics.

In Sum

You would not have the lifestyle you have if it weren’t for metals. Imagine a life with no modern transportation, communications, or conveniences, and that is a life without metals. And yet, new inventions involving metals are introduced every year, so life with metals will probably be even more interesting 10 or 20 years from today.

Prototech Laser Can Make it Happen

Questions on metal fabrication services? Contact Prototech Laser in Chesterfield Michigan. Our full-service metal fabrication facility has the experience, capacity and capability to fulfill your manufacturing needs. Services include state of the art laser cutting, metal forming, welding and assembly and more.

Housing one of the largest laser cutting capacities in the industry, we offer beneficial solutions for industries including defense, automotive and industrial sectors. Call and speak to a specialist about your manufacturing needs today.